Product Development

Do you have a napkin sketch of a product that could support your core business? Or perhaps you need actual bio data to create a product, but don’t know where to start.

We can help you take an idea from conception to proof-of-concept, and beyond through our iterative product development process.

We are experts in actualizing ideas, and would be honored to shepherd you through the process of product development.

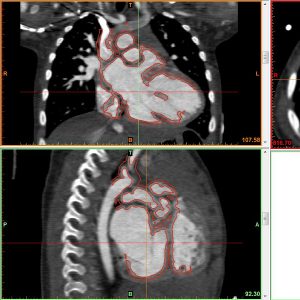

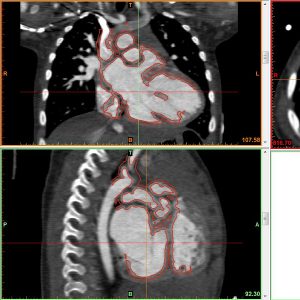

Medical Segmentation

If you want to simulate pediatric cardiac anatomy in order to demonstrate applications of your core products, the best starting point is oftentimes actual human data. We maintain a library of congenital heart defect imaging, and can additionally convert 2D images- yours or ours- into print-ready, 3D-digital models.

We utilize exclusively the only FDA approved software for image segmentation and 3D modeling in order to ensure the fidelity of our models, and efficiency of the process.

3D-Printing

The extended reach of Moore’s Law across technology is supported by the fast pace at which 3D-printing has evolved, from the ever-increasing array of materials, to the improving resolution, to a corresponding decrease in price.

Further, the materials available for 3D-printing are constantly expanding. It is now possible to recreate human tissue with surprising fidelity using flexible, suturable materials. Conversely, rigid multi-colored anatomic models are also possible- and at a ever-decreasing price point.

OpHeart will guide you through the 3D-printing process, and optimize your designs, particularly with respect to tolerances, print layout, material selection and production method given the order quantity.

We can source the best 3D-printing options for you, based on number of prints needed, material quality of prints, intended use and cost considerations.

Injection-Molding

Injection-molding is a process that can take 3D-printing to the next level for small-quantity orders. By using 3D-printing to create molds of your custom products, we can create a cost-effective solution for orders from 10 to 1,000, and can additionally achieve significant material flexibility at a low price.